New machines

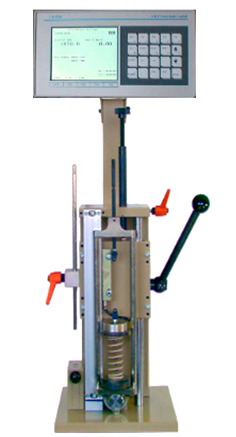

KB 2000F Spring testing machines

© KB Prüftechnik

© KB Prüftechnik

The KB 2000F is a newly developed motorised spring testing machine from KB Prüftechnik. It is used to place and test compression and tension springs, and other elastic elements.

With optimum operating comfort, the spring testing machine offers the user a very wide range of possible operations and testing procedures.

- Bend proof C stands in one room design

- Maximum load 2000N

- Vmax = 2000mm/min

- Force transducer from 100N to 2000N

With this spring testing machine, it is possible to use various force sensors and additional force sensors. In this way, a very high force measurement precision is guaranteed in the area of 1N to 2000N. A protective device is included in the scope of delivery. On request, we deliver the spring testing machine with a table support, printer, plotter and accessories for testing tension springs.Now also available as KB5000F with maximum load up to 5000N.

FW 43F Spring testing machine

© KB Prüftechnik © KB Prüftechnik |

The spring testing machine FW 43 F has a two-pillar guide with 4 bearing points. The path is fed in by a turnstile, The fine tuning is carried out by a separate device. Two length stops are provided, which can be switched over with a mechanical slide. |

FW 33 Spring testing machine

© KB PrüftechnikThe spring testing machine WG 3/3 has a two-pillar guide with 4 bearing points. The path is fed in by a lever, the fine tuning is carried out by a separate device.

© KB PrüftechnikThe spring testing machine WG 3/3 has a two-pillar guide with 4 bearing points. The path is fed in by a lever, the fine tuning is carried out by a separate device.

Two length stops are provided (optional), which can be switched over with a mechanical slide. The device has a data output for the connection to a personal computer Windows 95/98/NT/ XP/ 7.

The measurement values of the spring testing machine are calculated in a continuous process, and can be traced at any time via the saved spring core line. For the spring testing machine, a commercially available printer with LPTCentronics interface can be used for protocol creation.

The testing machine can optionally be equipped with 10 N, 50 N, 100 N, 200 N or 500 N sensor. The lengthwise measurement is carried out using an incremental scale and is shown in 5 digits on the display. Resolution 0.01 mm. For compression springs, a lengthwise infeed (optional) is possible up to 100mm, and for tension springs up to 150mm. The measurement plate, which can be adjusted to plane parallelism ,has a diameter of 45 mm.

- Force range 10 Newton

Measurement area: 0 - 10 N Res. 0.0001 N - Force range 50 Newton

Measurement area: 0 - 50 N Res 0.0005 N - Force range 100 Newton

Measurement area: 0 - 100 N Res 0.001 N - Force range 200 Newton

Measurement area: 0 - 200 N Res. 0.002 N - Force range 500 Newton

Measurement area: 0 - 500 N Res. 0.005 N

More information about FW 33 F

TG 8 Torsion spring testing machine

© KB PrüftechnikThe spring testing machine TG 8 for testing right and left-coiled torsion springs, with a parallel digital 6-digit torque and 6-digit angular display. The angle is measured in 3600 steps per rotation; this corresponds to a resolution of 0.1 degrees.

© KB PrüftechnikThe spring testing machine TG 8 for testing right and left-coiled torsion springs, with a parallel digital 6-digit torque and 6-digit angular display. The angle is measured in 3600 steps per rotation; this corresponds to a resolution of 0.1 degrees.

The device has a data output for connection to a personal computer. Spring Win, Windows 95/98/NT/ XP/ 7. The measurement values are calculated in a continuous process, and can be traced at any time via the saved spring core line. A commercially available printer with LPTCentronics interface can be used for protocol creation.

TG 9 Torsion spring testing machine

© KB PrüftechnikThe spring testing machine TG 9 tests right and left-coiled torsion springs with a parallel digital 3.5-digit torque and 5-digit angular display. The angle is measured in 3600 steps per rotation; this corresponds to a resolution of 0.1 degrees.

© KB PrüftechnikThe spring testing machine TG 9 tests right and left-coiled torsion springs with a parallel digital 3.5-digit torque and 5-digit angular display. The angle is measured in 3600 steps per rotation; this corresponds to a resolution of 0.1 degrees.

The spring testing machine has a data output for connection to a PC. The measurement values are calculated in a continuous process, and can be traced at any time via the saved spring core line.

A commercially available printer with LPTCentronics interface can be used for protocol creation.